October 30, 2023

According to the different laser cutting machine can be divided into: CO2 laser cutting machine, YAG laser cutting machine, fiber laser cutting machine, according to the structure can be divided into: gantry laser cutting machine, cantilever laser cutting machine, laser cutting machine robot. According to the power can be divided into: high, medium and low power fiber laser cutting machine; according to the cutting material can be divided into: metal and non-metal laser cutting machine.

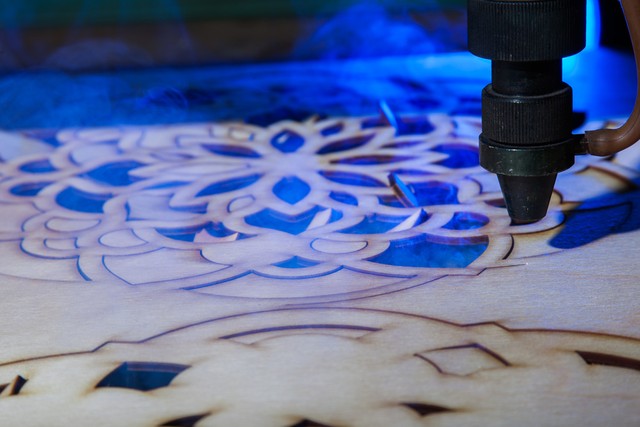

I. Fiber Laser Cutting Machine Because it can be transmitted through optical fiber, handheld laser engraver & laser cutter has unprecedented flexibility, few failure points, easy operation and maintenance, and extremely fast speed. So the fiber cutting machine has a great advantage in cutting thin plates within 4mm, but due to the wavelength problem of solid laser, the quality is poorer when cutting thick plates.

Second, YAG laser cutting machine

YAG solid state laser cutting machine has the characteristics of low price and good stability, but its energy efficiency is generally less than 3% . Now the output power of most products is as follows. laserpecker 11 pro used for punching, spot welding and plate cutting.

Third, CO2 laser cutting machine

CO2 laser cutting machine can stably cut carbon steel, stainless steel and aluminum alloy within 8 mm. There are various methods of laser cutting machine, mainly as follows:According to the laser light source, there are several different as follows, such as laser cutting machine, laser marking machine, etc. using instantaneous sealed CO2 laser tube. Laser marking machines and laser engraving machines also use CO2, but called RF tubes. The market leader in laser accessories is well known in the industry. Laser accessories are also available in a range of product structures such as laser welding and laser cutting.

According to the different types of processing enterprises in China, it can be best categorized into two kinds of metal CNC laser cutting machine and non-metal CNC laser cutting machine. Laser accessories use a laser beam with high energy density to heat the workpiece, so that the temperature change rises rapidly, in a very short period of time to reach a material boiling point, the material development begins to vaporize to constitute steam. Laser accessories are also studied laser welding, laser cutting and a series of related products market structure.

According to the cutting material can be divided into more specialized parts, such as stainless steel (stainless acid-resistant steel) laser cutting machine, carbon steel (C) laser cutting machine, aluminum (Al) laser cutting machine, copper laser cutting machine, alloy (alloy) steel laser cutting machine.

Related articles:

Pocket mine engraving machine to engrave your creative daily life as you wish!

Laser engraving and cutting machine is indispensable for the technological innovation of modern dail

Sketches become prototypes with the great flexibility of a laser cutter

Posted by: nydeliv at

03:16 AM

| No Comments

| Add Comment

Post contains 479 words, total size 4 kb.

35 queries taking 0.0242 seconds, 71 records returned.

Powered by Minx 1.1.6c-pink.